Professional Services

Whether your challenge can be solved by our existing products or requires the development of new analytics solutions and market design approaches, our team is ready to help.

DYNAMIC RESERVES DIMENSIONING

Determine optimal reserves volume

Using machine learning and advanced analytics, TSOs are able to dynamically adapt their reserves volume to the real imbalance risk faced by the system.

Avoid over- and under-procurement of reserves

With the deployment of intermittent renewable energy sources at a large scale and the development of large HVDC cables, the system imbalance is becoming more volatile and complex to anticipate ; some days exhibit a high risk of imbalance whereas other days exhibit a lower risk. With imbalance risk becoming more dynamic, the dimensioning of the operating reserves is becoming increasingly challenging.

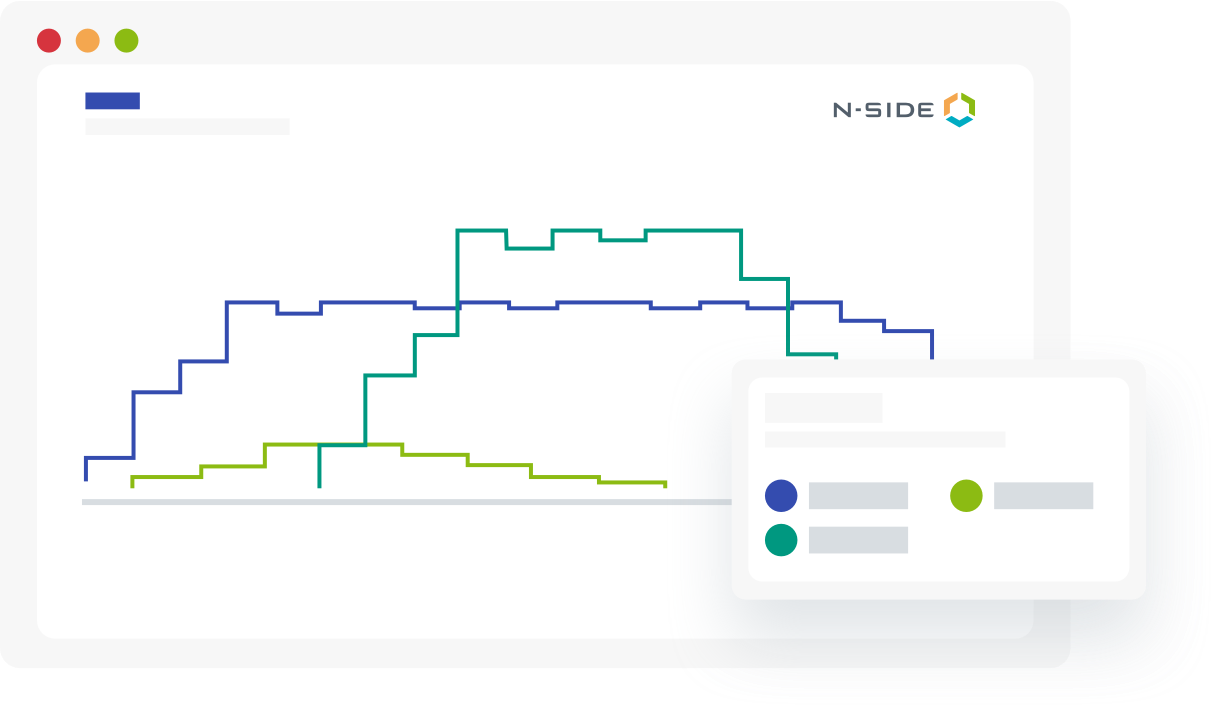

N-SIDE Dynamic Reserves Dimensioning enables transmission system operators to move closer to a real-time dimensioning approach, allowing them to better adapt reserves to match imbalance risk.

The solution leverages a combination of machine learning algorithms and Monte Carlo simulations to predict the normal imbalance and disturbance risk for a given period (e.g. in day-ahead with hourly granularity) and to compute the optimal reserves volume needed to reach the desired reliability target (e.g. 99%).

It takes into account day-ahead system conditions, such as load/wind/solar forecast, HVDC forecast, and power plants schedules.

Dynamic Reserves Dimensioning is used in production by Elia, the Belgian TSO. The solution increases the efficiency of the TSO in line with the Clean Energy Package and is compatible with SOGL.

HOW IT WORKS

Achieve accurate estimates of

imbalance risk.

Dynamic Reserves Dimensioning recommends reserves volume (balancing capacity) adapted to real imbalance risk, with more reserves for risky periods and fewer reserves for safe periods, to reach the desired reliability target and secure the grid.

For each period, the imbalance risk is estimated based on system conditions such as forecasted load, forecasted wind generation, and forecasted solar generation. The most relevant system conditions depend on each specific grid.

The solution combines three analytics modules:

1. Forecast Errors Imbalance Risk Module — Estimates the imbalance risk linked to errors on forecast (e.g. wind, PV, load) based on machine learning clustering algorithms

2. Rare Events Imbalance Risk Module — Uses Monte Carlo simulations to estimate the imbalance risk linked to rare but impactful events such as forced outages of generation plants or inter-connectors.

3. N-1 Incident Management Module — Applies post-processing rules to handle additional requirements such as covering the largest possible incident (N-1).

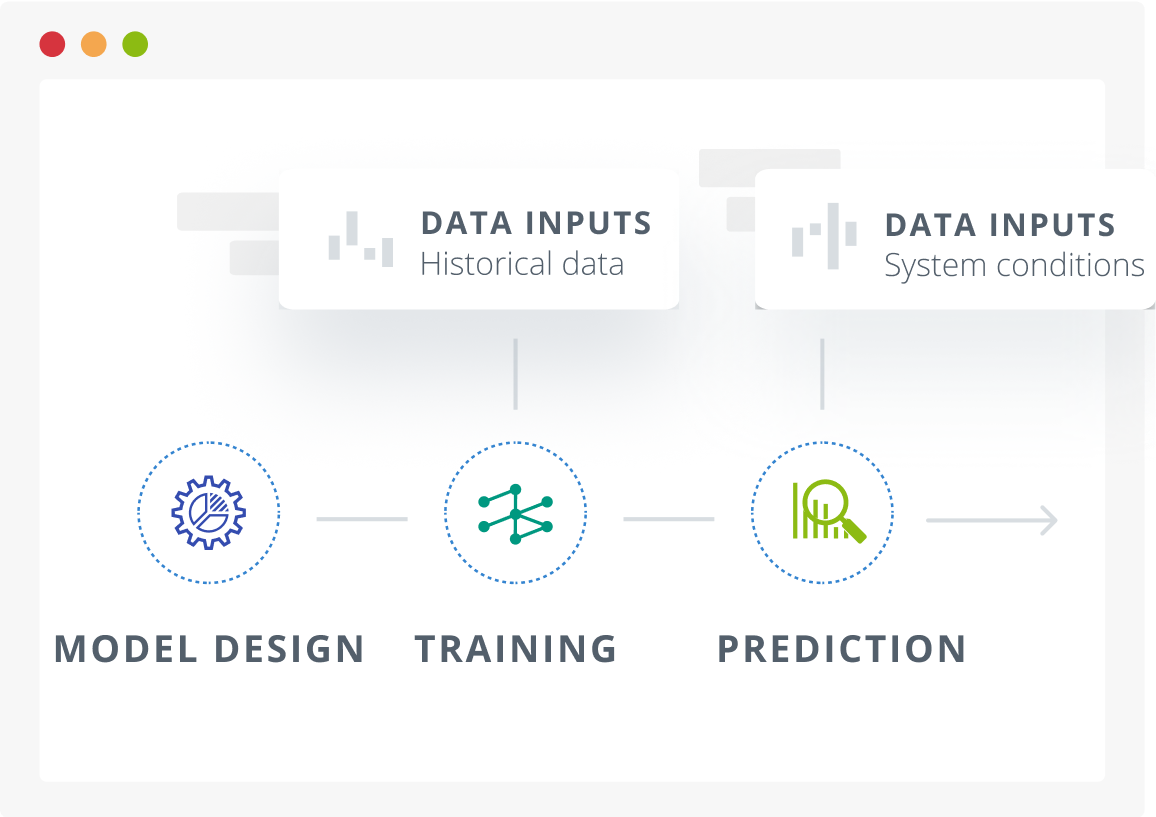

In operations, the solution is applied in three successive steps:

1. Model design — Prior to deployment, system conditions that best capture the imbalance risk are selected based on the state-of-the- art features engineering machinery. This selection combines analytical and business knowledge in order to guarantee the interpretability of the final machine learning model. Other parameters are also tuned.

2. Training — On a regular basis (e.g. once per month), the historical data used by the machine learning model are updated and the model is re-trained to integrate the latest trends.

3. Prediction — Every day, the model is run on day-ahead system conditions in order to estimate the system imbalance risk for the next day and recommend the optimal reserves volume.

Production

services

Production planning optimization

N-SIDE experts can help you optimize all steps of manufacturing and drug flow (e.g. quantities, timing, allocation) across the clinical supply chain, from formulation to packaging and beyond.

Adapt your manufacturing to real-time events, manage risks, and plan up to 10 years out. If you have scarce resources, a complex manufacturing network, or a large amount of products, this service delivers valuable visibility, control, and waste reduction.

Strategic manufacturing

decisions optimization

Many important decisions need to be made in R&D manufacturing/CMC. Outsourced or in-house manufacturing? Which network should I use? What’s the optimal stability plan? What’s the best way to handle scale-up to Phase 3 and the transition to commercial?

N-SIDE clinical manufacturing specialists will use our software to optimize the most important strategic decisions for your program, delivering important cost savings and waste reduction.

End-to-end

services

Change management

Transitioning to a digital, data-driven clinical supply chain requires more than technology; it demands adaptation throughout the business.

N-SIDE experts will support your change management journey, starting with a clear vision associated with measurable added value for R&D efficiency.

Keeping this purpose in mind, N-SIDE will help your teams take advantage of advanced analytics to become a truly data-driven organization.

End-to-end program optimization

By optimizing manufacturing for the entire clinical program and optimizing supply for each individual trial, we can typically free up to 50% of the initially planned quantities and accelerate time to commercialization by 2-6 months.

We accomplish this by reducing drug needs at the trial level and limiting manufacturing waste. That enables us to either cancel production lots and re-allocate the resources to new programs, or to re-invest that drug into increased sites and recruitment speed.

N-SIDE Suite

support services

SUPPORT

Implementing the Supply App, Production App, or the entire N-SIDE Suite?

Implementation support needs differ depending on your project and internal resources. N-SIDE provides tailor-made implementation and change management services to help you realign your processes and reduce time to value.

N-SIDE offers comprehensive training to onboard your team to our tools and technologies. There are different training tracks for the different roles that will interact with the N-SIDE Suite.

Training sessions are led by N-SIDE experts who bring different concepts to life through hands-on exercises and explanations of case studies.

Discover all training options in our training catalogue

In addition to structured training sessions, N-SIDE experts are also available for one-on-one coaching.

Use this time to ask specific questions about N-SIDE software and apply what you learned in training to your own projects.

“N-SIDE supports our business with advanced analytics tools which allows us to realize the energy transition. Their experts provided the knowledge to transform our reserve dimensioning to the state-of-the-art, ready to deal with future renewable power systems.”

Kristof De Vos System Services Manager, EliaBenefits

Dynamic Reserves Dimensioning enables TSOs to reach a better reliability level in the risky days, as compared to a static dimensioning that only targets a reliability level on average.

Static approaches tend to oversize general FRR needs to cover risky periods. Our dynamic approach avoids useless FRR volumes in safe periods.

Our machine learning models produce explainable decisions, avoiding the black-box effect.

TSOs can significantly reduce FRR procurement costs as a direct result of volume reduction.

Up to 10% decrease in yearly reservation costs

50 MW reduction of average FRR needs at Elia

99% Reliability target reached at all times, not only on average

Related Services

Match-integrate-support

Our match-integrate-support service is a step-by-step approach to facilitate the gradual adoption of our software products while mitigating risk within your organization.

learn more

Market design

These services range from state-of-the-art market and algorithm modeling and analysis to quantitative simulations and cover both long-term and short-term markets for capacity, energy, and balancing.

learn more

Co-creation

With our co-creation approach, we tackle new challenges together with our clients by applying cutting-edge techniques from the extensive N-SIDE analytics toolbox.

learn moreFeatured resources

RESEARCH

Dynamic dimensioning approach for operating reserves: Proof of concept in Belgium

A peer-reviewed article in Energy Policy discussing this new method for the sizing of operating reserves by electric power system operators.

Go To PDF

PARTNER RESOURCE

Report from Elia on Dynamic Reserve Dimensioning

N-SIDE provided all calculations and modeling for this study by Elia, the Belgian TSO.

Download PDF

REPORT

Sizing of balancing capacity in the presence of network constraints

Report published on IEEE Transactions on Power Systems in collaboration with Svenska kraftnät detailing how we precisely cast the problem of dimensioning Frequency Restoration Reserves in a multi-area setting.

Read the report